Squeeze casting, SQC, also known as liquid-metal forging, is a hybrid process which combines features of forging and casting in one operation. It is a process in which molten metal solidifies under pressure within closed dies under a hydraulic press. By pressurizing the liquid metals while they solidify, near-net shapes can be achieved in in the sound, fully dense castings. The process generates the highest mechanical properties attainable in a cast product.

The general principle of squeeze casting is simple. The liquid metal is accurately metered and poured slowly into the lower half of the preheated, lubricated steel die to maintain laminar flow. Once the metal begins to freeze, the top die or punch is brought down into the die cavity and maintained under high pressure to feed the casting to compensate for shrinkage until solidification is complete. The press loads are much lower than those required for conventional forging. On completion of freezing, the punch die element is raised and the casting ejected. The casting ejection and handling are done in much the same way as in closed die forging.

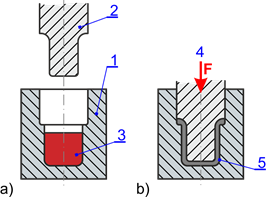

a) press is opened, bottom die half is filled by metal

b) molten metal is pressed, solidification takes place; 1 – stationary die half, 2 – movable die half – punch, 3 – molten metal,

4 – press movement, 5 – solidifying casting