The vacuum moulding process, or V-process, is an unbounded aggregate moulding process in which the aggregate, held in a moulding box, is positioned between two sheets of thin plastic films and is held in place by the application of vacuum. The plastic films form the shaped mould face and the flat mould back. The aggregate is thus supported by the atmospheric pressure until the casting is complete. Invented in Japan in 1972 and originally designed for the production of flat ornamental and art castings, this process is significantly different from other moulding processes. The process is now used worldwide for the industrial casting made of all metals. Dry, unbounded, free-flowing aggregate, usually silica sand, is used. Pattern plate must be adapted for this moulding method. The pattern and its plate contain a number of small vent holes. The mould is made in a special hollow-wall moulding box allowing the air drawing from its volume by a vacuum pumping system.

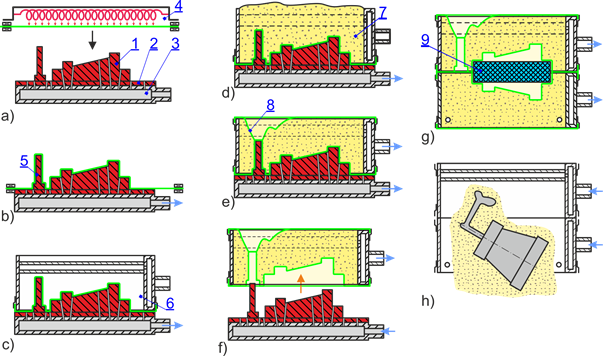

Vacuum moulding process;

a) heating of plastic film, b) draping the film over pattern, c) attaching moulding box, d) sand fill and vibration, e) second film applied to box, f) stripping,

g) drag and cope assembly, h) mould collapse after vacuum release;

1 – pattern, 2 – pattern board, 3 – hollow carrier plate, 4 – radiant heater, 5 – pattern film, 6 – special hollow moulding box, 7 – dry sand,

8 – backing film, 9 – conventional core