Sand slinger is a machine which delivers moulding aggregate and fills moulds at a high speed by centrifugal force. As the mould is filled with the aggregate, it is at the same time compacted by its own kinetic energy. The basic working part of the sand slinger is a sand-slinging head, a housing that contains a rotor with a blade. The rotor blade is balanced on the opposite side by the counterweight. The conveyor movement is synchronized with the blade turning by means of a cam mechanism. The moulding aggregate is fed by a conveyor to the blade which rotates at 1,500 rpm. The somewhat compacted lump of moulding aggregate is then thrown by centrifugal force into the moulding box at a high speed. The moulding aggregate is compacted in layers during consecutive movements of the slinging head over the area of the moulding box. The moulds made like this exhibit elevated strength, since a very dense mould can be made. Density is a function of the aggregate velocity and the thickness through which the high-velocity aggregate must compact a previously placed aggregate. Sand slingers are useful in rapid production of large moulds.

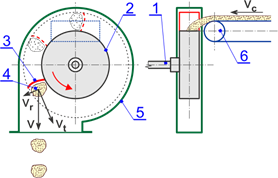

1 – shaft, 2 – rotor, 3 – blade, 4 – lump of moulding aggregate, 5 – housing, 6 – conveyor;

vr – radial velocity, vt – tangential velocity, v – net velocity, vc – conveyor velocity