Spin casting, also known as centrifugal rubber mould casting (CRMC), is a variation of centrifugal casting, rather centrifuging, which is used to cast a variety of small parts. It is a method of utilizing centrifugal force to produce castings from a semi-permanent, vulcanized silicone rubber mould. Typically, a disc-shaped mould is spun vertically around its central axis. The casting material, alloy of low melting point, is then poured in through an opening at the top-centre of the mould. Centrifugal force then sends the material through the gates, towards the periphery of the mould, where the cavities of the castings are located. The filled mould then continues spinning as the metal solidifies. Aside from the low-melting point alloys (based on zinc, tin or lead), liquid thermoset resins and plastics can be used, as well as the pattern wax for investment casting. Therefore, the process is well suited also for rapid prototyping.

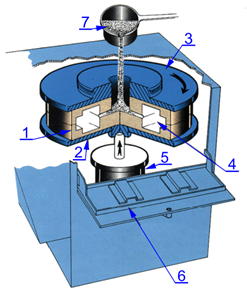

1 – silicone rubber mould, 2 – mould clamp plate, 3 – mould cover plate,

4 – mould cavities, 5 –air cylinder, 6 – loading door, 7 – molten metal